Ukuphucula ukuchaneka kunye nokusebenza kakuhle: Ukuphonononga izinto eziluncedo koomatshini bokuwelda beeNkqubo ezininzi

Yazisa:

Kwimeko yemizi-mveliso yanamhlanje eguquka ngokukhawuleza, abashiseli bajongana nocelomngeni oluqhubekayo lokuziqhelanisa neentlobo ezahlukeneyo zetekhnoloji kunye neenkqubo zokuwelda.Ukuhlangabezana nezi mfuno, itekhnoloji ye-welding iye yavela kakhulu, ivula indlela yezixhobo eziphambili ezifanaezininzi inkqubo yokuwelda oomatshini.Ezi zixhobo zintsha zidibanisa ukuguquguquka kunye nokusebenza kakuhle ukuguqula ishishini le-welding.Kule bhlog, siza kuntywila nzulu kwihlabathi loomatshini bokuwelda beenkqubo ezininzi, sijonga izibonelelo zabo, izicelo kunye nendlela ababumba ngayo ikamva lokuwelda.

Funda ngoomatshini bokuwelda beenkqubo ezininzi:

Umatshini we-welding we-multi process sisixhobo esiphakamileyo esigubungela iindlela ezahlukeneyo zokuwelda, ezivumela iiwelders ukuba zitshintshe ngokungenamthungo phakathi kweenkqubo ezahlukeneyo zokuwelda.Aba matshini baphelisa imfuno yezixhobo ezininzi ezahlukeneyo, ukwenza lula inkqubo ye-welding kunye nokwandisa imveliso.Ngokuqhelekileyo badibanisa imisebenzi efana ne-MIG (i-Metal Inert Gas), i-TIG (i-Tungsten Inert Gas), i-wire welding kunye ne-flux-cored welding.

Izinto eziluncedo koomatshini bokuwelda beenkqubo ezininzi:

1. Ukuguquguquka:Enye yeenzuzo eziphambili zomatshini we-welding multi-process yikhono lokusingatha iinkqubo ezahlukeneyo ze-welding ngokulula.Ngokudibanisa iindlela ezininzi, abashiseli banokugqiba uluhlu olubanzi lwemisebenzi ngaphandle kokutshintsha izixhobo.Oku kuguquguquka kuhlangabezana neemfuno ezahlukeneyo zokuwelda kwimizi-mveliso yeemoto, yokwakha, yokuvelisa okanye yokulungisa.

2. Ixesha kunye nokusebenza kakuhle kweendleko:Ukuba nomatshini wokuwelda weenkqubo ezininzi kunokunciphisa kakhulu utyalo-mali lwezixhobo ngokubanzi.Esikhundleni sokuthenga oomatshini abahlukeneyo kwiinkqubo ezahlukeneyo ze-welding, abashicileli banokuthembela kwisixhobo esinye.Ukongezelela, ixesha eligcinwe kumatshini wokutshintsha kunye nokumisela izixhobo zeenkqubo ezahlukeneyo kunokunyusa ukusebenza kakuhle kunye nemveliso.

3. Ukwandisa indawo:Oomatshini bokuwelda beenkqubo ezininzi benza ukuba abatyibilizi bakhulise ukusetyenziswa kwendawo enyiniweyo yokusebenza.Idibanisa oomatshini abaninzi kwiyunithi edibeneyo, ukunciphisa imfuno yendawo yokugcina, iyenze ibe yinto efanelekileyo kwiindibano zocweyo ezincinci okanye iindawo zemisebenzi ezinendawo encinci.

4. Ukuchaneka okuphuculweyo:Aba matshini babonelela ngesetingi ezilungelelanisiweyo ezivumela iiwelder ukuba zilungelelanise iiparamitha ezahlukeneyo ezifana nombane, okwangoku, kunye nesantya sokutya kocingo.Oku kuchanekileyo kwenza abashicileli abanezakhono bavelise i-welds ezikumgangatho ophezulu ngokuchaneka okukhulu, amandla kunye nokuqina.

Ukuququmbela:

Oomatshini bokuwelda beenkqubo ezininzi baliqabane elifanelekileyo le-welder yale mihla, ebonelela ngeendlela ezahlukeneyo eziphuculweyo, ukusebenza kakuhle kunye nokuchaneka.Njengoko itekhnoloji ye-welding iqhubeka ihambela phambili, aba matshini babumba ikamva le-welding ngokuvumela iingcali ukuba zenze iinkqubo ezahlukeneyo ze-welding ngokulula.Ukusuka ekongeni ixesha kunye nemali ukuya ekwandiseni iindawo zokusebenza kunye nokuphucula umgangatho weweld, oomatshini bokuwelda beenkqubo ezininzi benza utshintsho kwishishini lewelding kwaye bahlangabezana neemfuno zanamhlanje ezihlala zitshintsha.Ke, nokuba ungumchweli onamava okanye unomdla wokuzilibazisa, ukwamkela aba matshini bokusika ngokungathandabuzekiyo baya kuthatha izakhono zakho zokuwelda kwiindawo eziphakamileyo.

Ividiyo

Isicelo

Oomatshini bokuwelda beenkqubo ezininzi basetyenziswa kakhulu kumashishini ahlukeneyo, kubandakanywa ukwenziwa, ukwakhiwa kwezindlu, ukwakha iinqanawa, i-aerospace kunye nemizi-mveliso yeemoto.Ukulungelelaniswa kwabo kunika ukuguquguquka kokusingatha uluhlu olubanzi lwezinto ezibandakanya intsimbi, i-aluminium, insimbi engenasici kunye nokunye.Ngokomzekelo, kwiivenkile zokulungisa iimoto, aba matshini basetyenziselwa ukulungisa umzimba nokuwelda inxalenye ye-injini.Ukongeza, oomatshini bokuwelda beenkqubo ezininzi bazuzisa iingcali zokuwelda ezisebenza kwiiprojekthi ezahlukeneyo ngaphandle kokutshintsha izixhobo.

laser welding machine Imiqathango yokusetyenziswa

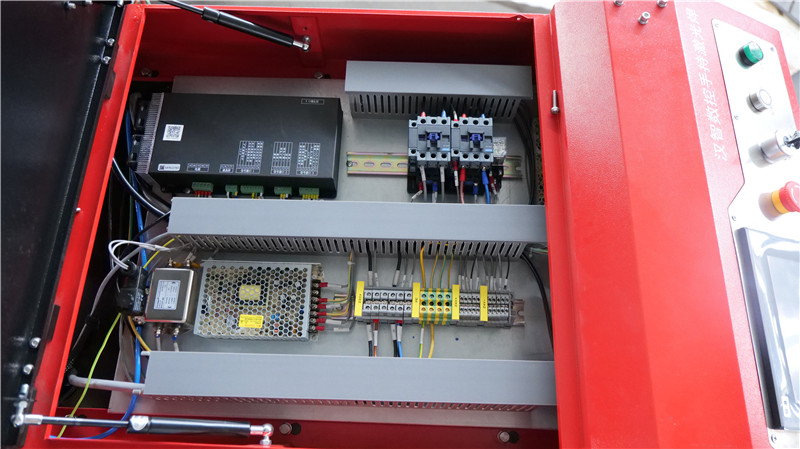

1. Nxiba iimpahla zokukhusela, iiglavu kunye neeglasi xa usebenzisa umatshini we-laser welding.2. Nceda uqinisekise ukuba zonke iindawo zomatshini zigcinwe kakuhle kwaye zisemgangathweni ngaphambi kokusetyenziswa.3. Qinisekisa ukuba indawo yokusebenza ifakwe umoya kakuhle ukukhusela ukuqokelela kwezinto ezinobungozi ngenxa yemisebenzi ye-welding.4. Ngethuba lokusebenza komatshini we-laser welding, nceda ubeke ingqalelo kwiingozi ezinokubakho ezifana nomlilo, umsi okanye iintlantsi.5. Khangela uqhagamshelo okanye iingcingo ezinokukhubazeka phambi kokusetyenziswa, kwaye uthathe amanyathelo okhuseleko ayimfuneko xa kukho imfuneko yokuphepha nayiphi na ingozi yokothuka kombane eyayanyaniswa nombane womatshini okanye izinto zawo zangaphakathi/iisekethe.6. Xa usenza imisebenzi ye-laser welding kwiintsimbi ezifana nentsimbi kunye ne-aluminium, umgama okhuselekileyo kufuneka ugcinwe kwizinto ezinokutsha ezifana nephepha kunye neplastiki, ezinokutsha phantsi kweemeko ezithile.7. Musa ukutshisa izinto ngokuqhuba iipulses ezide kakhulu, oku kunokuphazamisa inxalenye edibeneyo okanye kubangele umonakalo we-thermal kwindawo ejikelezileyo.8. Qaphela ukuba ulahle amaqhekeza ashushu aphuma emva kwenkqubo ye-soldering.

iinkcukacha zibonisa