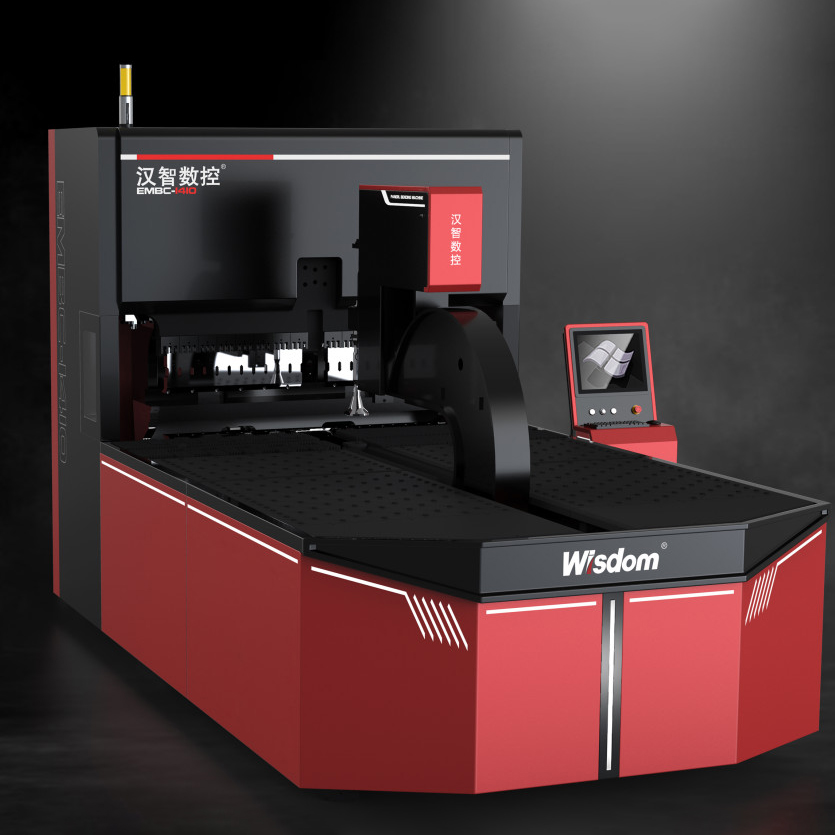

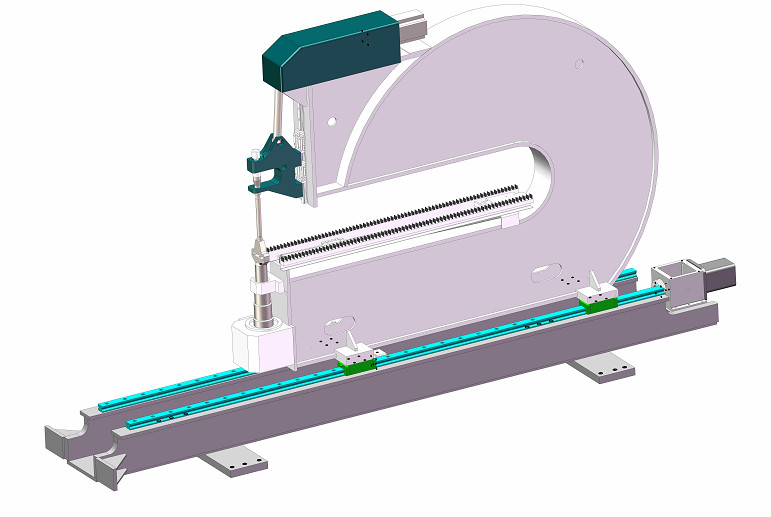

Iphaneli yeSemi-automatic Bender EMBC 1402

ukucaciswa kweemveliso

| Hayi. | Igama | Ipharamitha | Iyunithi |

| 1 | Ubuninzi.ubude | 1400 | mm |

| 2 | Ubukhulu.ububanzi | 1400 | mm |

| 3 | Min.Ubude bokugoba | 200 | mm |

| 4 | Min.ukugoba ububanzi | 260 | mm |

| 5 | Ubukhulu be-Max.bending (MS, UTS410N/mm²) | 1 | mm |

| 6 | Ubungqingqwa obuncinci (MS, UTS410N/mm²) | 0.5 | mm |

| 7 | Max.ukugoba ukuphakama | 170 | mm |

| 8 | Imowudi yokulungelelanisa ubude yocinezelo oluphezulu Incwadi | ||

| 9 | Ukusetyenziswa kwamandla okuphakathi | 2.2 | KW |

| 10 | Ubunzima | 15 | T |

Iimpawu kunye nesakhiwo esiphambili

Ngokumalunga noyilo lomatshini kunye nokuveliswa, iHebei Hanzhi CNC Machinery Co.,Ltd.ikakhulu igxile kwezi ngongoma zilandelayo:

1. Ingcamango yokuthengisa elandela ukusebenza kunye nokugcina umsebenzisi yonke ipeni.

2. Ingqikelelo yoyilo ethembekileyo kakhulu kwaye echanekileyo.

3. Iimathiriyeli ezikumgangatho ophezulu, iinxalenye ezithengiweyo kunye nobuchule obugqwesileyo bokucubungula.

4. Ugxininiso olungakumbi ekusebenziseni lula kunye nokugcinwa kunye nokhuseleko.

5. Izinga lokugcinwa okuphantsi kunye neendleko zokugcina kwishishini elifanayo.

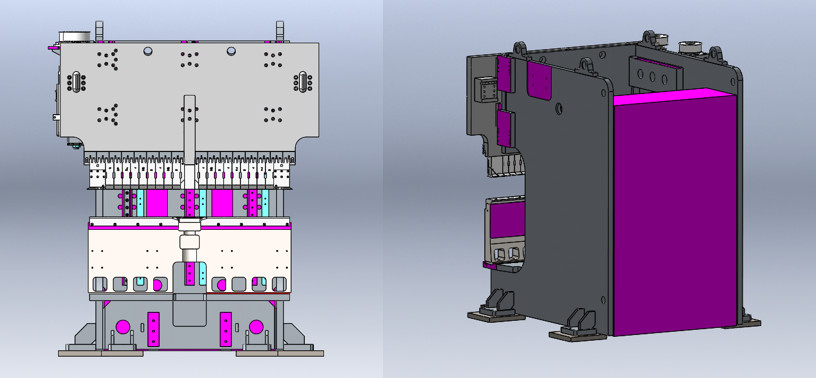

isakhelo

A. Ukwakha imodeli ye-3D enomda: Ngokusekwe kwimodeli eqinileyo ye-3D ephuhlisiwe neyiliweyo, imodeli yesici esiguqukayo yenzelwe ukubalo.Imodeli iqwalasela amacandelo aphambili kuqhagamshelwano lokudluliselwa kwamandla.Imikhosi idluliselwa kwi-bearing ngokusebenzisa uxhulumaniso kwaye emva koko uhlalutyo lwamandla lokuthwala lwenziwa.

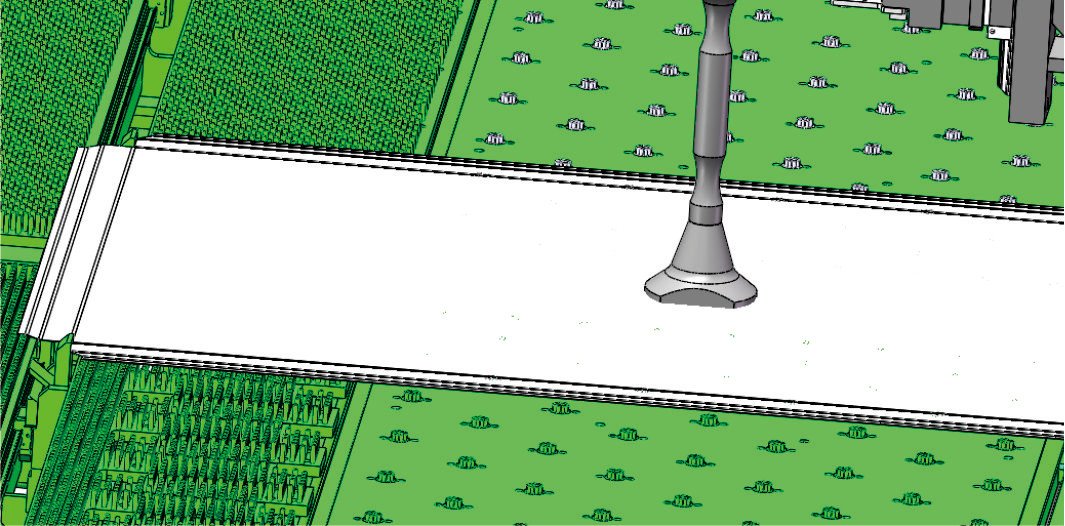

Umzobo 1 Iphaneli bender Finite element eguquguqukayo imodeli yomatshini opheleleyo

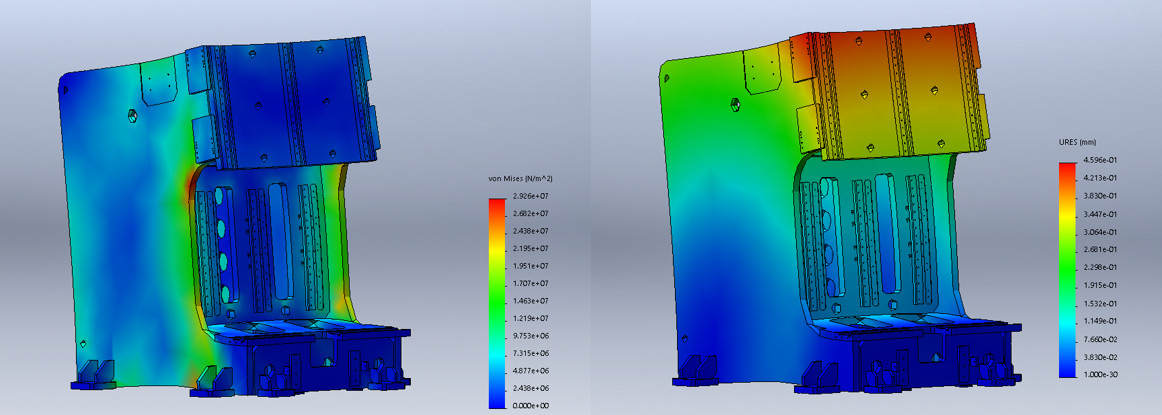

B. Uhlalutyo lweziphumo ze-Static Analysis: Ngenxa yesantya esicothayo somatshini, uhlalutyo lwamandla lungancitshiswa kwingxaki engatshintshiyo.Ngokusekelwe kumthwalo wokunyanzeliswa kweplate kunye nomthwalo wokugoba kwicala elithe nkqo lentloko ye-cutter, uxinzelelo kunye neziphumo ze-deformation ziboniswe ngezantsi.Uxinzelelo oluphezulu lubonakala emqaleni womzimba ngoxinzelelo oluphezulu lwe-21.2mpa kunye ne-deformation ephezulu ibonakala kwindawo ephezulu yomzimba kunye ne-deformation ephezulu ye-0.30mm.

Ngokweziphumo zokuhlalutya izinto ezinqamlekileyo zesakhelo, intsimbi ye-Q345 yakhethwa njengezinto eziphathekayo;i-carbon dioxide shield welding yamkelwa;unyango olushushu lwenziwa ukuphelisa uxinzelelo oluveliswa yi-welding;ngaloo ndlela iqinisekisa ukuchaneka, ukuzinza kunye nokuqina okuphezulu kwezixhobo zokusebenza kwexesha elide.

Umzobo we-2 wokuxinzezeleka koxinzelelo lokuhlalutya iziphumo zesakhelo

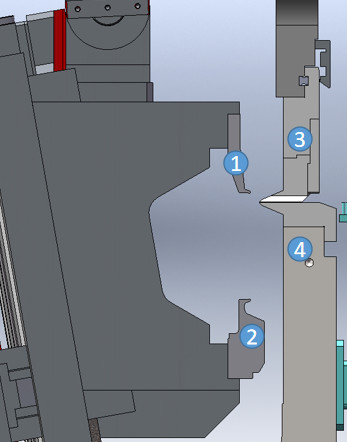

Inkunzi yegusha ephezulu

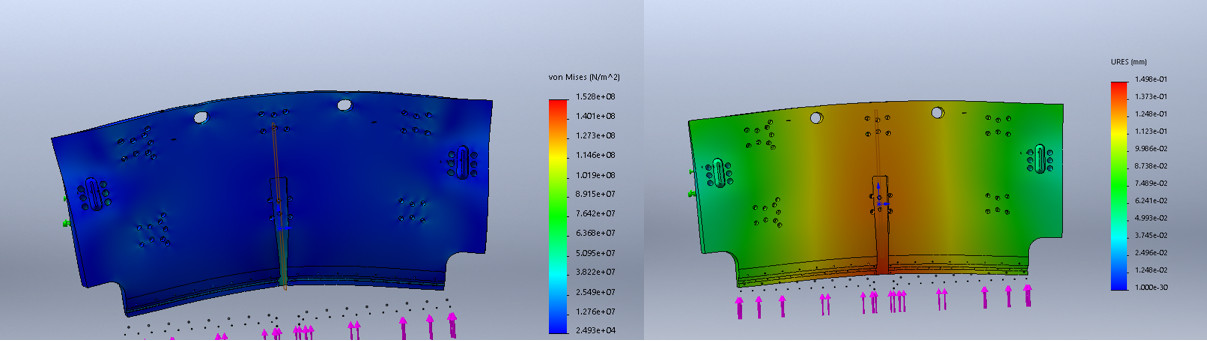

Le nxalenye ikakhulu iqulathe isilayidi, isikrufu setorque ephezulu, isinciphisi, isikhombiso sikaloliwe, i-servo motor njalo njalo.I-drive ephambili ilawulwa yi-servo motor kunye nemodi yokulawula i-servo synchronous control, enokuqinisekisa ngokufanelekileyo ukuchaneka kokumisa, isivinini esikhawulezayo kunye nokulawulwa okuphezulu.I-lubrication ye-screw ekhokelayo kunye nesikhokelo sikaloliwe yamkela ukuthanjiswa okuzenzekelayo, kunye negrisi yi-00 #, eqinisekisa ubomi benkonzo kunye nokuchaneka kwe-screw yokukhokela kunye nesikhokelo sikaloliwe ixesha elide lokusebenza.

Iziphumo zohlalutyo oluqinileyo lwesilayidi esiphezulu: umzobo wokufuduka kwezintso kwitafile ephezulu ubonisa ukuba uxinzelelo oluphezulu lubonakala kwindawo ephezulu, uxinzelelo oluphezulu luyi-152mpa, i-deformation ephezulu ibonakala kwindawo ephezulu yetafile, eyona deformation iphezulu. yi 0.15mm

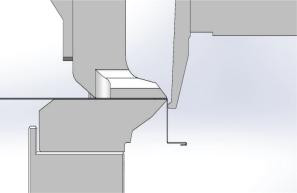

Umzobo we-3 iziphumo zohlalutyo lokufuduswa koxinzelelo lwenkunzi yegusha

Ngokweziphumo zokuhlalutya izinto ezinqamlekileyo zenkunzi yegusha, intsimbi ye-Q345 yakhethwa njengesixhobo;I-CO2 ye-welding ekhuselekileyo isetyenzisiwe;unyango lobushushu lwenziwa ukuphelisa uxinzelelo olubangelwa ukuwelda;ngaloo ndlela iqinisekisa ukuchaneka, ukuzinza kunye nokuqina okuphezulu kwezixhobo zokusebenza kwexesha elide.

Iyunithi yokugoba

Inxalenye yamandla okuqhuba iyunithi yokugoba iqhutywa yi-servo motor ngaphandle kokubandakanyeka kwenkqubo ye-hydraulic, enenzuzo enkulu ngokubhekiselele ekunciphiseni ukugqoka kunye nokukrazula kwamacandelo kunye nokusebenza kakuhle kokuhanjiswa, ngokuhambelana nokugcinwa kwamandla kunye nomgaqo-nkqubo wokukhusela indawo ekhuthazwayo. ngurhulumente.

Ngokutsho kokumiselwa kolwazi lwephepha, inkqubo ibala ngokuzenzekelayo indawo ye-higher press knife 3 kwaye ilawula umgama phakathi kwe-high knife 3 kunye ne-4 press knife ukulungisa iphepha;ngokuhambelana nenkqubo yokumisela, nokuba oku kugoba kuphezulu okanye phantsi, i-knife ephantsi yokucinezela i-2 okanye i-knife ephezulu ye-1 ilawulwa ukuba ihambe ngokukhawuleza kwindawo yokugoba;ngokweengile ezahlukeneyo zokucwangcisa, imela egobayo ilawulwa ukuba ihambe isiya kwindawo ebalwayo ngokusebenzisa ifomula yokubala i-angle enelungelo elilodwa lomenzi wokugqibezela ukugoba.

Ngokweendlela ezahlukeneyo zokugoba, inokohlulwa ibe yi-engile ukugoba, ukugoba kwe-arc enkulu, ukugoba ukugoba, njl. njl., yeyiphi ukugoba i-engile eyahlulahlulwe ibe kukugobela phezulu kunye nokugobela ezantsi.

Iyunithi yokushicilela ephezulu

Umzobo.6 Iyunithi yokucofa okuphezulu

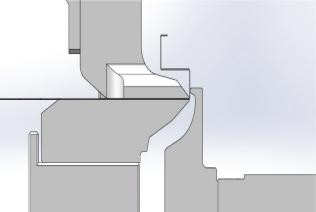

Iyunithi yokushicilela ephezulu: inxalenye yazo zonke iinkqubo zokugoba, i-EmbC epheleleyo ye-servo multilateral bending centre ixhotyiswe ngeyunithi ekhethekileyo yokushicilela ephezulu enokuthi ifakwe kwaye ilungiswe ngesandla kwiiplate ezahlukeneyo zobude.

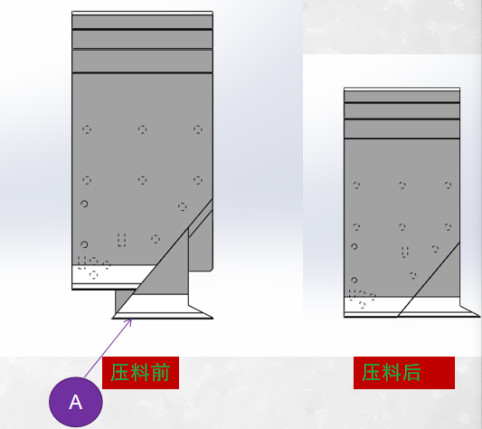

Ukuze sihlangabezane neemfuno zebhokisi yokugoba yokuphepha, siye saphuhlisa ukufa okukhethekileyo kokuphepha.Phambi kokucinezela, inxalenye yokunqanda ukufa ikwilizwe phambi kokuba ucinezele kumzobo kwaye ukutya kuqale.Emva kokutya, ikwimeko emva kokucinezela kumzobo kunye nokugoba kuqala.Emva kokugoba, isilayidi esiphezulu siyahamba.Ngethuba lokushukuma kwesilayidi esiphezulu, inxalenye A iya kuhamba ngokuzenzekelayo kwisimo ngaphambi kokuba ucinezele.Emva kokuba isilayidi esiphezulu siye kwindawo emiselweyo, intshukumo elandelayo iqala.

Fig.7 Ukugoba ibhokisi yokuphepha

Isixhobo

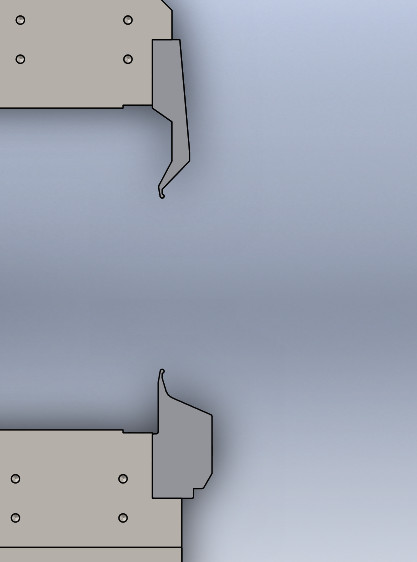

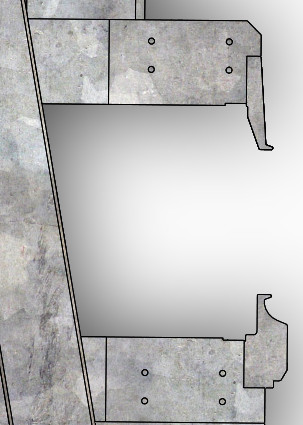

Izixhobo zokugoba zahlulwe zibe zizixhobo zokugoba eziphezulu kunye nezixhobo zokugoba ezisezantsi.Izixhobo zokugoba ezikhethekileyo zinokwenziwa ngokwezifiso ngokweemfuno ezahlukeneyo zomthengi.

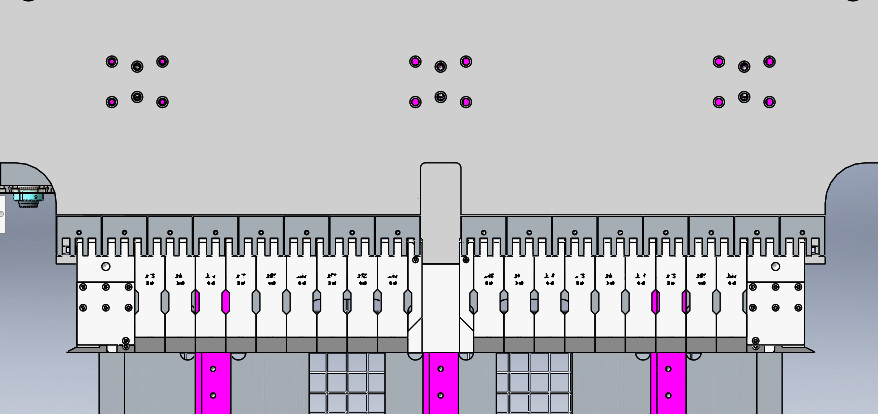

2.Iyunithi yokutya ngePlate:

Ukuhamba, ukudibanisa kunye nokujikeleza kwe-sheet metal kulawulwa yi-robot 1, i-fixture 2 kunye ne-disc ejikelezayo 3 ngokulandelanayo.Ngethuba lenkqubo yonke yomatshini, ukondla kwe-sheet metal kulawulwa yi-servo motors, eyenza i-automation kunye nokumisa ngokukhawuleza, ukunciphisa amaxesha okuhamba kunye nokwandisa ukusebenza kakuhle.Ngombulelo kwizinto ezintsha zesakhiwo kunye nokusetyenziswa kolawulo olupheleleyo lwe-servo, i-clamping kunye nokujikeleza kwe-sheet metal iyakwazi ukugcina ukuchaneka kuyo yonke inkqubo yokusebenza yeziko le-multilateral bending.Kwimisebenzi emininzi entsonkothileyo, kunye ne-polygonal, ukuchaneka okujikelezayo okuqhubekayo kwe-0.001 kunokuqinisekiswa.

3. Iyunithi yokubeka iPlate:

Iyunithi yokubeka ipleyiti inephini yokubeka ekhohlo, iphini yokubeka yasekunene, iphini yokubeka ngaphambili kunye nephini yokubeka yangasemva;izikhonkwane zokubeka ekhohlo nasekunene beka ipleyiti ekhohlo nasekunene.Iphini yokubeka yangaphambili kunye nephini yokubeka yangasemva ilawula indawo yangaphambili nasemva kwepleyiti kwaye iqinisekisa ukuba ipleyiti ihambelana neemela zokucinezela eziphezulu nezisezantsi, ezisetyenziselwa ukuqinisekisa ukuchaneka kokubeka ipleyiti.

Iyunithi yokubeka ipleyiti inokumisa ngokuzenzekelayo ipleyiti kwaye igqibezele ngokuzenzekelayo ukugoba kwamazwe amaninzi ngexesha elinye, elinciphisa kakhulu ixesha lokugoba, lilawula impazamo yokucheba yepleyiti ekugobeni kokuqala kwaye iqinisekise ukuchaneka kokugoba.

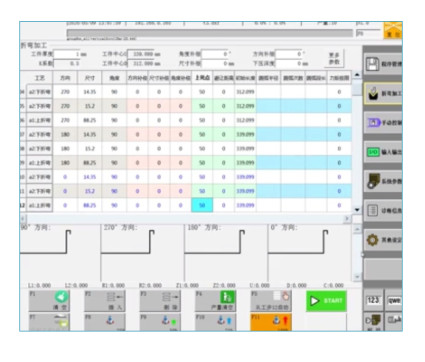

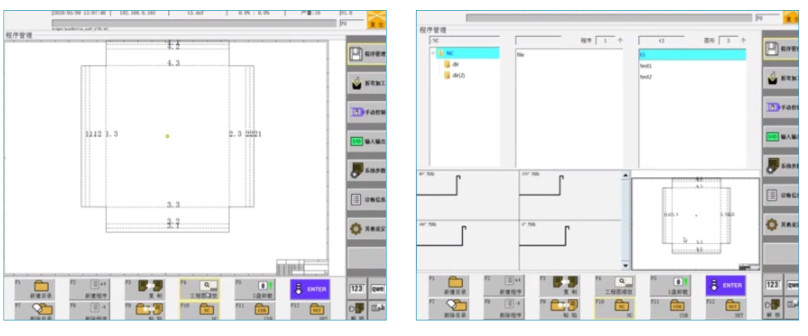

Inkqubo ye-4.CNC

A: Iinkqubo ze-CNC eziphuhliswe ngokudibeneyo kunye nesoftware ingasetyenziswa kwaye ilawulwe ngokukhawuleza nangokulula

B: Iimpawu eziphambili.

a) .Indlela yokulawula ibhasi ye-EtherCAT enokumelana nokuphazamiseka okuphezulu

b) Ukuxhasa inkqubo ngokuthe ngqo, ukugoba idatha kwisinyathelo ngasinye kunokungenwa kwifom

c) Inkxaso yokugoba okugobileyo

d) Ulawulo olupheleleyo lwe-servo yombane

e) Inkxaso yokugoba imbuyekezo

f) Inkxaso yenkqubo emacala mabini

Umsebenzi weprogram ye-2D, ukungenisa idatha ye-2D DXF yokudweba, ukuvelisa ngokuzenzekelayo inkqubo yokugoba, ubungakanani bokugoba, i-angle yokugoba, i-angle yokujikeleza kunye nezinye iinkcukacha.Emva kokuqinisekiswa, ukuqhutyelwa kokugoba okuzenzekelayo kunokwenziwa

Uluhlu lwenxalenye ephambili

| Hayi. | Igama | Uphawu |

| 1 | Isakhelo | Ubulumko |

| 2 | Isixhobo | Ubulumko |

| 3 | Iyunithi yokugoba | Ubulumko |

| 4 | Inkqubo ye-CNC | Ubulumko |

| 5 | Servo motor | Ubulumko |

| 6 | Umqhubi we-Servo | Ubulumko |

| 7 | Isiporo | Ubulumko |

| 8 | I-Ballscrew | Ubulumko |

| 9 | Isinciphisi | eTaiwan |

| 10 | Umqhekezi | Schneider |

| 11 | Iqhosha | Schneider |

| 12 | Inxalenye yombane | Schneider |

| 13 | Intambo | Yicu |

| 14 | Ukutshintsha okukufutshane | uOmron |

| 15 | Ukuthwala | SKF/NSK/NAICH |

4) Uyilo, ukuveliswa, ukuhlolwa kunye nokufakwa kwesixhobo somatshini kuhlangabezana nale migangatho ilandelayo.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Inxalenye esecaleni kunye noluhlu lwezixhobo

| Hayi. | Igama | Qt. | Phawula |

| 1 | Ibhokisi yesixhobo | 1 | |

| 2 | Faka iphedi | 8 | |

| 3 | II-hexagon spanner | Iseti e-1 | |

| 4 | Umpu wokufaka amafutha ngesandla | 1 | |

| 5 | Incwadana yemigaqo yeCNC | 1 | |

| 6 | isipanela esivulekileyo | 1 |